Also, in phrases of design, you'll typically have to convert the paintings to a vector format and separate the colors when mytshirtkings. Much of it depends on the capabilities of the print shop you’re using.

Relax, it’s solely the first round.DTG relies on process printing, or theCMYKcolor model to make the various shades of colour. At One Hour Tees, we can't only create the right customized t-shirt for you or your organization, however we’ll also have it shipped or delivered to you or your event when you want it.

Think about somebody operating a 5K in the summer with a thick, solid layer of plastic masking their chest. In the printing business, element is the smallest elements of the design, which may include fantastic lines, small type, textures, or tiny elements like within the example under. The main cause is that the underbase isn’t opaque enough, so the shirt shade bleeds via. Darker shirts and shade shirts can simply turn out to be a problem when making an attempt to color match.

Ink will appear barely “raised” due to the nature of the silk screen process. Remember the software you use to manage your DTG printing business is just as necessary as your printer. Screen printing administration software like Printavo can be used for DTG printing too. Epson is famous for his or her large-format printers, and is a standard household name with many years of expertise in inkjet printing. For a typical CMYK DTG printer , there could also be $1,200 worth of ink within the printer at any given time.

This implies that sure kinds of t-shirt designs are higher suited to each methodology. If you’re seeking to design and print your own custom t-shirts, you’ve likely encountered these two phrases — DTG printing and display screen printing. Now you’ve learn some more about each method of t-shirt printing; you can see how completely different they're. There’s at all times going to be a greater option, and it’s going to rely on your particular person needs as to which is the best for you.

If the ink is applied too thick, it can weigh down the front of the shirt, or wherever the print sits. This is especially essential for all of the lightweight blends which are so in style at present. With display printing within the lead, DTG must get busy as we enter the sixth round. But credit score where credit is due– it’s a closer struggle than anticipated. Screen printing doesn’t have this sturdiness problem if it’s accomplished right.

With some printers, the method is straightforward and low-cost but with others, such as the Espon F2000, the method is dear as a lot of ink is wasted. Then again, the printers wanted plenty of maintenance and weren't very user-friendly. The current models have climbed to an entire new degree – they'll print on darker-colored garments using lighter-colored inks without any issues and they are much more user-friendly. The gear used in display screen printing are fairly bulky and wish a lot of house – most undoubtedly not a back-office affair. Here are the advantages and downsides of using warmth transfer to print apparels. Screen printing specialty inks can elevate a T-shirt design like nothing else, and significantly increase the worth for resale.

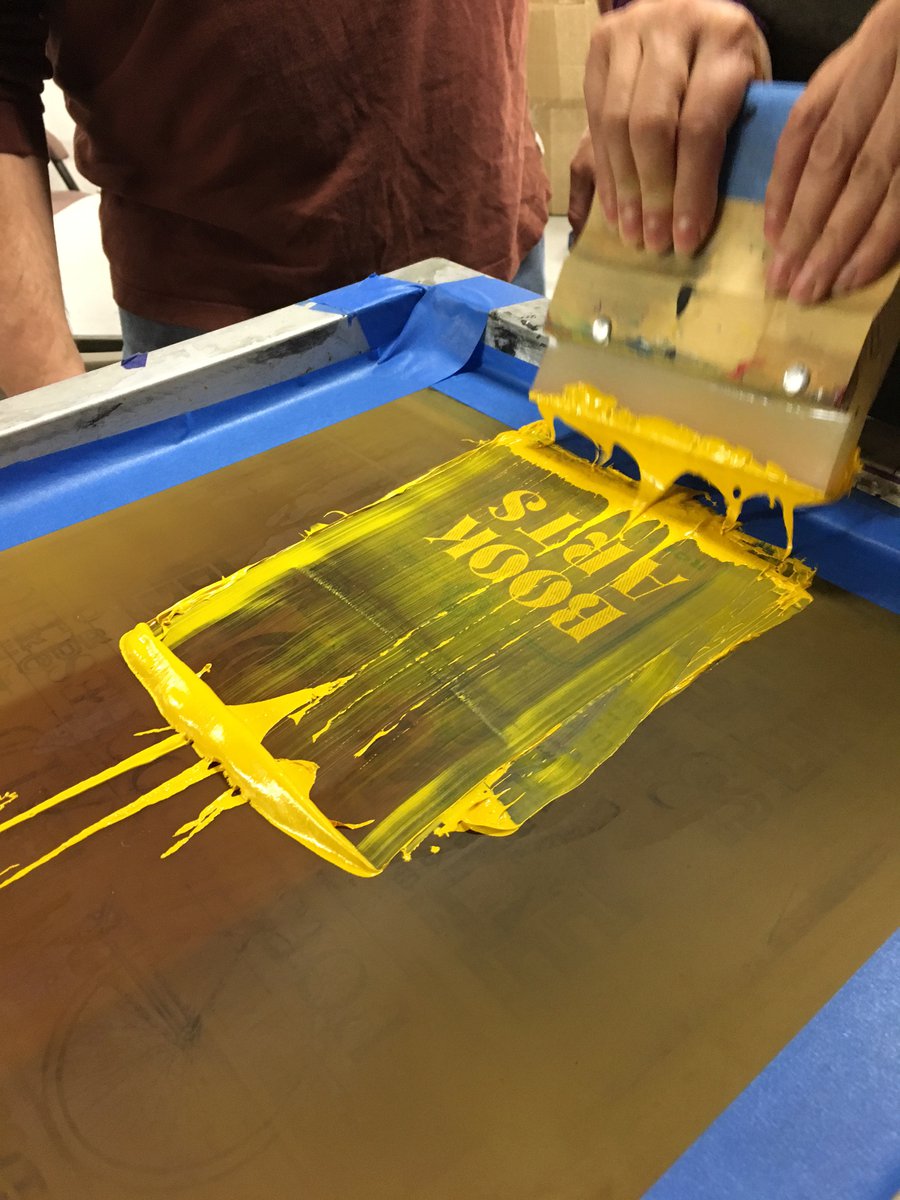

Screen printing is often carried out by making use of ink through a mesh-like stencil of the design. This is usually a guide process, and hence labor-intensive.

Sure, if the ink isn't utilized accurately or not cured properly, even Plastisol can begin to fade or deteriorate. But all of us have that shirt in our drawer from the household reunion 20 years ago that is nonetheless holding on. DTG makes use of halftones as nicely, but these digital machines can print as much as 1200 DPI, and use diffusion dither. To get extra technical, it is a frequency modulated halftone as a substitute of an amplitude modulated halftone. It can generally result in a grainy look, however a significantly better reproduction of small particulars. When it comes to display printing, it’s all the time about “holding” detail. Pantone matching could be accomplished with process inks and particularly with inkjet printing– and is finished, all day each day– in other printing mediums.

Many envision a future where prospects order on-line and a DTG printer automatically prints the shirt. While many businesses have attempted this, the technical and labor challenges have confirmed large . DTG printing just isn't so easy as pushing a button – there are tons of variables and factors to assume about. The display screen is positioned on a display screen printing press and registered so it's going to correctly align on the printing surface (typically, a t-shirt). Ink is pressed via the openings in the stencil with a squeegee, instantly making use of ink onto the printing surface. Using greater than the beneficial number of colours slows down the process, although, leading to higher final costs, since each shade used needs its own display stencil created.

Learn more about pod DTG printing in our information to DTG printing with Luke Ryerkerk. One approach to get around that is to do a "pod printing" setup. But that isn't always the case – and DTG printing is not at all times the easiest way to realize softer prints. A number of Chinese manufacturers are also beginning to bring their DTG choices to market, either immediately or by partnering with major brands. These DTG machines are prime quality, and heaps of DTG producers source many of their components from China . They have a litany of choices and services that span past DTG printing – and a formidable assist staff armed with plenty of academic resources. With many years of expertise in embroidery technology, Ricoh has begun its acquisition and growth part.

A pre-treatment machine typically costs between $3,000 and $4,000. Don’t underestimate the significance of your pre-treatment machine!

There are certain situations where you'd positively need to opt for DTG over silk screening, and vice versa. The result is a t-shirt with a customized printed design that's as high quality as anything you’d find in a high-end division retailer. [newline]Their Freejet printers are a desktop possibility, whereas they also provide the Cheetah – a large, industrial DTG printer. Brother has made a reputation for itself in the DTG house with their versatile and highly effective GTX line of printers.

The printing single color dtg vs screen printing is of very top quality – the printer produces full color images. Direct to Garment is an Inkjet innovation that prints immediately onto garments. When this know-how was first invented, there have been plenty of issues with printing onto dark-colored materials using lighter-colored inks notably white. Silk screening is usually a very profitable business but you’ve obtained to have good working space.

Both DTG printing and display printing supply a high quality completed product. However, because display printing entails a unique display screen for each detail and shade, printing intricate designs could be time-consuming. The quality and the sturdiness are still incredibly good regardless of what sort of textile you're utilizing.

As with all printing methods past and present, there are a couple of limitations with screen printing. Screen printing is a multi-step course of that is greater than one hundred years old. Simply put, the printing course of includes pushing ink by way of a stenciled mesh display screen on to a substrate, which is the t-shirt in our case. The final printing technique that exists is Dye Sublimation and this is sometimes paired with Cut and Sew as a ending method.